3D printing is more and more remodeling the medical sector. Whether or not it’s to develop exoskeletons, cancer-fighting units or tailored medicines, additive manufacturing has confirmed its price time and time once more. Right now, we flip our consideration to Singapore, the place researchers at Nanyang Technological College (NTU) have developed an revolutionary 3D printed ‘lively’ cloth utilizing this expertise.

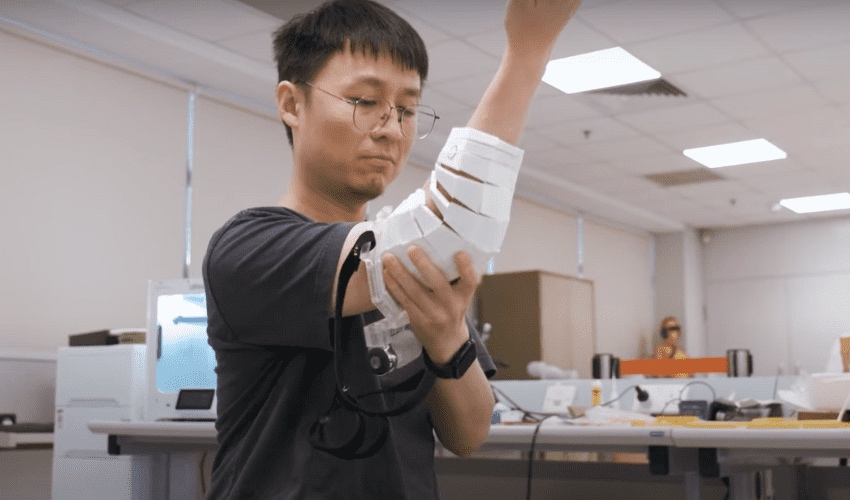

Known as RoboFabric, this adaptable, versatile cloth can stiffen at will, making it significantly helpful for medical units and versatile robotics. NTU researchers have designed an elbow brace with RoboFabric, enabling it to help heavier hundreds, in addition to a prototype wrist help designed to stabilize joints, serving to Parkinson’s sufferers handle their tremors.

RoboFabric: A 3D Printed Material That Reduces Muscular Effort

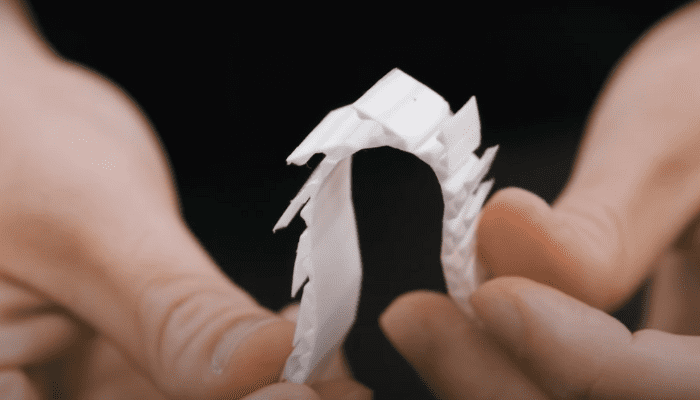

The revolutionary new cloth, impressed by the pure buildings of the pangolin and octopus, is designed by a mathematical algorithm to create interlocking tiles. These tiles, produced by 3D printing, are linked by metallic fibers. When the fibers contract, they trigger the tiles to interlock, growing the rigidity of the RoboFabric by greater than 350 occasions.

The outcomes of this analysis, revealed within the journal Superior Supplies, present that the usage of this gadget can cut back human muscular effort by 40%. Assistant Professor Wang Yifan of Nanyang Technological College and chief scientist, defined that their inspiration got here from animals, which use complicated buildings to endow their limbs with a number of functionalities, much like octopuses’ capacity to alter form and rigidity.

This scientist envisions that, within the close to future, sufferers will be capable to use customizable, versatile limb helps as a substitute of conventional inflexible casts. These units could be easy to use or take away on the contact of a button, providing better help to the aged by decreasing the muscular effort required to raise heavy objects of their every day lives.

How Was It Made?

Customization begins by downloading a 3D scan of the wrist or elbow. This program makes use of a sophisticated algorithm to create geometric patterns for 3D printing. Subsequent, metallic fibers are inserted via openings between the printed segments and linked to {an electrical} gadget that controls cable stress to regulate rigidity.

Affiliate Professor Loh Yong Joo from Tan Tock Seng Hospital highlighted the promising purposes of this expertise in drugs. He defined that it may present essential help for joint accidents and supply assist to individuals with motor problems, resembling these affected by Parkinson’s illness or higher limb weak point.

What do you consider this new 3D printed cloth from NTU? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly publication right here for the most recent 3D printing information straight to your inbox! You can too discover all our movies on our YouTube channel.