Additive manufacturing is commonly seen as a greener various to conventional manufacturing strategies and mass manufacturing, which generates excessive emissions. One purpose for that is that 3D printing solely provides supplies the place they’re truly wanted, thus lowering waste. Though the sustainability advantages of 3D printing rely upon the method, supplies and elements used, it provides many alternatives to make trade extra sustainable and respectful of our assets. The UN’s Sustainable Improvement Targets are additionally encouraging trade to pursue greener methods, akin to local weather safety measures or extra sustainable consumption and manufacturing patterns. On this article, we current ten explanation why 3D printing is taken into account extra sustainable, and the potential of this manufacturing know-how for a extra environmentally pleasant future.

#1: Discount of Waste and Materials

In comparison with conventional manufacturing strategies, 3D printing provides benefits by way of waste discount. On the whole, subtractive processes akin to turning, drilling or sawing generate extra materials waste, for instance within the type of chips. This drawback doesn’t come up with 3D printing, as the fabric is used straight for the layer-by-layer building of the thing. Nonetheless, it should be said that the era of waste varies relying on the know-how, as powder and resin printing processes generate extra waste than different 3D printing applied sciences because of the want for help buildings or extra powder that can not be totally reused. Nonetheless, by exactly planning the required materials, software program capabilities can optimize the 3D mannequin to reduce materials utilization. This ensures a extra environment friendly use of assets and reduces power consumption and machine emissions.

3D printing includes printing straight onto the constructing platform, which minimizes materials waste (picture credit: Devrimb)

#2: Native Manufacturing

Historically, many merchandise are sourced from distant places, resulting in international dependency and provide chains that impression our native economic system and setting. Nonetheless, because of native 3D printing, firms are capable of produce their merchandise straight throughout the group with out counting on exterior provides, thereby lowering CO2 emissions. It additionally avoids using packaging usually related to the transportation of elements.

#3: On-Demand Manufacturing

On-demand manufacturing can also be linked to native manufacturing. Corporations can manufacture merchandise flexibly and in keeping with demand, which considerably minimizes overproduction and the necessity for inventories. Spare elements should not have to be saved in inventory, however could be produced as wanted. The flexibleness of additive manufacturing makes it attainable to supply personalized merchandise that meet the person wants of consumers and thus guarantee demand-oriented manufacturing, which may result in a discount in industrial processes sooner or later.

On building websites specifically, 3D printing, particularly concrete 3D printing, is used on web site, making building extra sustainable (picture credit: Heidelberg Supplies)

#4: Service Life Extension Via Restore

The reusability of elements by way of 3D printing additionally promotes the round economic system. In trade, the DED (Direct Power Deposition) course of is commonly used to restore broken elements by making use of materials layer by layer to the present elements as an alternative of producing them from scratch. The method reduces the necessity for brand new uncooked supplies and extends the service lifetime of elements. Nearly all weldable metals can be utilized for this goal, which will increase the flexibleness and effectivity of the restore course of.

#5: Recycling and Upcycling

Misprints, faulty or not required print initiatives can probably be melted down and reused for the manufacture of recent merchandise. Thermoplastic supplies akin to ABS, PETG or PLA specifically supply these recycling choices. Nonetheless, this nonetheless not often occurs. The know-how is beneficial for upcycling used merchandise by combining waste merchandise with 3D-printed workpieces and creating progressive one-offs. Regardless of the benefits talked about, recycling supplies additionally poses a problem, as the standard of the fabric should be excessive sufficient to be reused in a printing course of. Multi Jet Fusion allows a sustainable method right here with its reusability fee of as much as 80% of used materials and powder mattress fusion applied sciences may supply the potential for reusing as much as 98% of the powder, however because of the lack of research surrounding this, that is unsure.

The Print your Metropolis challenge transforms plastic waste into furnishings utilizing 3D printing (picture credit: Print your Metropolis)

#6: Eco-Pleasant Supplies

Many sustainable supplies at the moment are out there for 3D printing, that are both recyclable or bio-based. Along with conventional metals and plastics, new supplies that may cut back the ecological footprint are more and more getting used. Examples embrace biodegradable supplies akin to filaments constructed from corn starch, espresso grounds, sugar cane or wheat waste, which could be disposed of in a extra environmentally pleasant method. PLA, which is constructed from pure uncooked supplies akin to corn, is especially well-known. By including by-products, the filament could be nearly 100% bio-based. PLA can also be biodegradable in industrial composting crops (even when its sustainability has been questioned). Non-fossil plastics akin to PET or PHA constructed from renewable uncooked supplies and recycled filaments constructed from ABS and PET additionally help the round economic system. Nonetheless, the sustainability of all these supplies is dependent upon numerous elements, together with the uncooked materials supply, compatibility with ecosystems, transportation routes and recyclability. Steady analysis, experimentation and enchancment of present supplies may cut back environmental impacts sooner or later.

#7: Power-Saving Manufacturing

By combining a number of capabilities in a single manufacturing run, 3D printing provides alternatives to avoid wasting power. A major benefit lies within the power effectivity of the top product. Within the aerospace sector, weight discount by way of 3D printed elements results in decrease gasoline consumption and a discount in emissions in comparison with historically manufactured elements. Through the use of much less filler materials and extra environment friendly materials utilization, 3D printing allows sooner manufacturing with decrease power consumption. Moreover, particular filaments can be utilized which have a decrease melting level or a print mattress insulated with aerogel that may preserve temperatures as much as 60°C with nearly no extra energy consumption. Different measures that may be taken embrace insulating the print head with silicone or rock wool, which reduces warmth loss, or constructing an enclosure across the printer to forestall temperature loss.

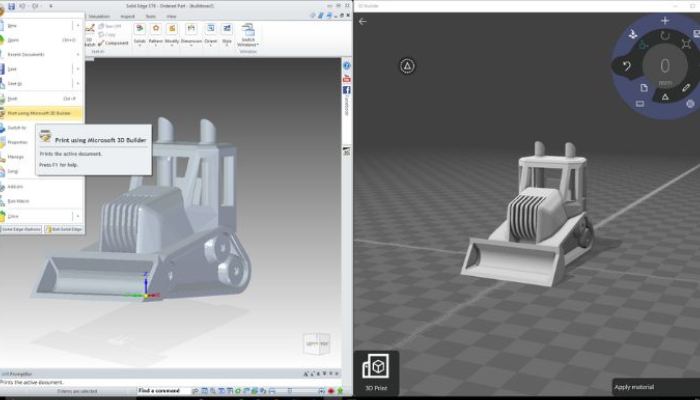

Utilizing software program, you may optimize your design to avoid wasting materials (picture credit: Strong Edge)

#8: Optimized Design Via Software program

The usage of 3D modelling software program allows efficient design optimization, lowering materials consumption and printing time and selling environmentally pleasant manufacturing processes. Digital simulations assist to take away pointless particulars and help buildings and a few software program offers instruments for early error detection and defect evaluation throughout 3D CAD design. The software program options make it attainable to check fashions digitally, saving materials and power by way of pointless take a look at prints. The digital switch of CAD designs additionally reduces the necessity for manufacturing services and lowers transportation prices and emissions. As well as, the light-weight design allows materials financial savings by way of lowered filling and elevated wall thickness. Manufacturing complicated assemblies as one-piece elements reduces materials and power consumption. Work is at present underway on new processes that use synthetic intelligence to detect and proper printing errors in actual time.

#9: Environmental Safety Tasks

3D printing not solely provides the potential for extra environmentally pleasant manufacturing, but additionally makes an efficient contribution to the preservation of species and the environment. For instance, the know-how is used to copy nature with a view to print coral, nests, reefs or beehives and to supply animals which have misplaced their shelter as a consequence of local weather change with a synthetic dwelling that’s an identical to their pure habitat. The corporate can also be concerned in ocean conservation initiatives and the manufacturing of meat alternate options. This not solely protects animals, but additionally reduces CO2 emissions, because the consumption of 1 piece of beef generates as much as 12 kg of CO2. Numerous firms use additive manufacturing to supply plant-based meat, which guarantees a 95% decrease environmental impression in comparison with typical meat manufacturing.

Divers deliver a 3D-printed reef to the seabed (picture credit: xtreee.com / Greg Lecoeur)

#10: Analysis and Innovation

Final however not least, the edge for prototype growth and experimentation in 3D printing could be very low. This enables firms and innovators to implement new concepts rapidly and develop sustainable options. This flexibility ends in fixed product and know-how enhancements, particularly with regard to environmental safety. Many firms and start-ups are actively devoted to the additional growth of additive manufacturing with a view to make it extra environment friendly and much more environmentally pleasant. This progressive power opens up new potentialities for inventive functions and industrial processes and ensures that 3D printing is constantly optimized by way of its sustainability.

Do you suppose that 3D printing is extra sustainable? Are there any main causes we not noted? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly publication right here for the newest 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.